Pool Products

Bond Kote™

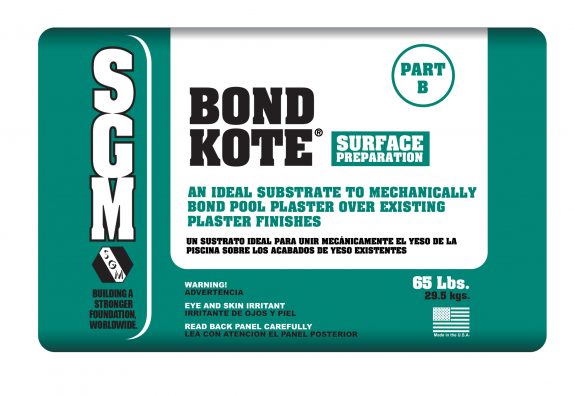

Bond Kote™ is a specially formulated, two-part cementitious coating, designed to be used as an ideal substrate to mechanically bond pool plaster over existing plaster finishes.

Product Details

LIMITATIONS

All materials and surfaces to be coated should remain between 50°F (50 degrees Fahrenheit) / 10°C (ten degrees Celsius) or below 100° F (100 degrees Fahrenheit) / 38°C (38 degrees Celsius) 24-hours prior and 24-hours after installation. Do not apply in rain or extremely high humidity. Protect the “Liquid Resin” from freezing. Plaster should be applied to Bond Kote™ within fourteen (14) days or reapply Bond Kote™.

PACKAGING

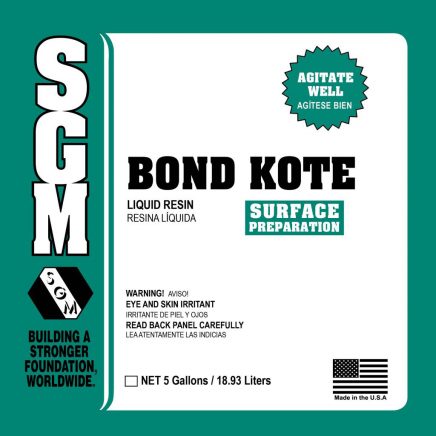

SGM Bond Kote™ is formulated in units consisting of two (2) 65 lbs. bags of a factory blended dry cement mix and one (1) five-gallon container of liquid resin.

SURFACE PREPARATION

Check completely for hollow areas and remove all loose plaster. Remove all mildew, algae, fungus, and rust by either sandblasting or with an acid wash which must be followed by neutralization with soda ash. If the surface is unusually soft, painted, peeling or flaking, then the surface must be heavily sanded or water blasted. Regardless of the method used, thoroughly wash down with a “jet nozzle” hose and let the pool drain until there is no standing water present. Substrates should be prepared in a manner that leaves the CSP concrete surface profile rough and porous enough to ensure that Bond Kote can achieve a good chemical and mechanical bond to the substrate. Well prepared surfaces shall have the ability to absorb water prior to the application of Bond Kote.

- NOTE: Special attention is required on pools below the water table and or leaking.

MIXING

Make sure the “liquid resin” is mechanically agitated before use to disperse all settled solids. Then pour the “liquid resin” (five-gallons) into a clean mixing container with flat bottom. Add Bond Kote™ (two 65 lbs. bags) while continuously mixing with a mechanical mixer. Continue mixing for two (2) to four (4) minutes until Bond Kote™ is completely dispersed. NEVER USE LESS THAN 115 LBS. OF DRY MIX PER FIVE-GALLONS OF LIQUID RESIN.

APPLICATION

To check the consistency of material, apply Bond Kote™ with 1-¼” nap roller onto a vertical test area. Let material set for one (1) minute; then, using a clean textured roller, rough up surface to the desired finish. Material thickness can be adjusted by adding a small amount of “cement mix” if too thin or “liquid resin” if too thick. Adjust only one (1) time. DO NOT RE-TEMPER MIX. Once Bond Kote™ is mixed to correct consistency, apply immediately — do not let material stand unused. Apply the mixed Bond Kote™ with 1-¼” nap roller to steps at the shallow end of the pool and let material set for approximately one (1) minute; then, rough up the surface to the desired finish with a clean textured roller as done in the test area. Continue this same process with the wall areas and then proceed to the floor surface last. Starting at the deep end of the pool make sure the application is uniform in thickness and texture. The wet membrane thickness needs to be at least 80 mil .08 (2.023mm). While applying Bond Kote, check the depth of the coating occasionally with a wet film thickness gauge.

CURING

The minimum cure is reached in six (6) hours; setting and drying time may vary according to atmospheric conditions. For best results wait for 24-hours before plastering.

PLASTERING

Mist Bond Kote™ with clean cool water prior to plastering to permit proper hydration. Make sure Bond Kote™ is free of any foreign matter before plastering.

COVERAGE

One (1) unit covers 450—500 square feet of surface area. The wet membrane thickness needs to be at least 80 mil .08 (2.023mm). While applying Bond Kote, check the depth of the coating occasionally with a wet film thickness gauge.

CLEAN UP AND STORAGE

Clean hands, tools, and containers with warm soapy water.

- NOTE: USE NEW ROLLER WITH EACH APPLICATION.

CAUTION

This product may expose you to chemicals, including silica, which the State of California recognizes as a cause of cancer. For more information, visit the Proposition 65 Warnings Website (www.P65Warnings.ca.gov). Use NIOSH approved masks at all times to handle silica dust. KEEP OUT OF REACH OF CHILDREN.

SGM, Inc. warrants this product will perform in accordance with its intended use for a period of one year from the date of manufacture. Any claim for defective products must be submitted in writing to SGM, Inc., and samples of the defect must be provided. EXCEPT AS PROVIDED HEREIN, SGM, INC. MAKES NO OTHER REPRESENTATION OR WARRANTY OF ANY KIND, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE. IN NO EVENT SHALL SGM, INC. BE LIABLE FOR DAMAGES OF ANY KIND OR NATURE, WHETHER ARISING BY CONTRACT, TORT OR OTHERWISE. SGM, INC.’S SOLE OBLIGATION WILL BE TO REPLACE ANY PRODUCT DETERMINED BY SGM, INC. TO BE DEFECTIVE.